Railroads serve as lifelines of transportation, connecting cities, industries, and communities across vast, and sometimes congested, landscapes. In this scenario, maintenance practices – of the rolling stock, infrastructure and Maintenance of Way – are critical factors in the integrity and safety of these networks.

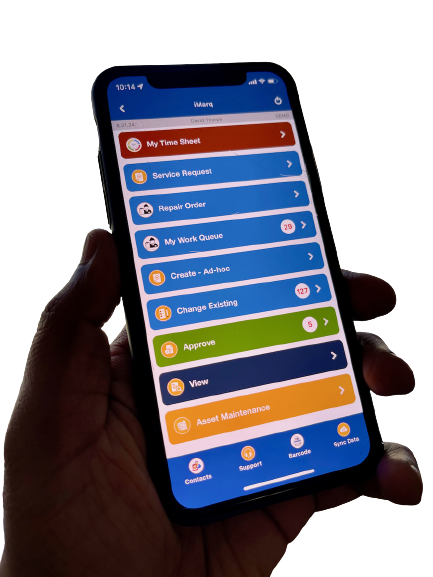

Traditionally, maintenance processes in this industry have been reactive with substantial manual / paper-driver processes, leading to increased costs, operational inefficiencies and, indeed, safety lapses. The need of the hour is digitization and proactive maintenance strategies to overcome these hurdles, optimize operations, and meet regulatory / safety standards. Recognizing the need for this transformation is Connixt iMarq. As a mobile-first maintenance platform, iMarq is a valuable addition to RELAM, empowering the organization to gain better visibility, make way for effective resource allocation, and increase labor efficiency by doing away with all manual processes.

iMarq has provided RELAM with comprehensive equipment health monitoring, enabling real-time visibility into the condition and performance of their heavy equipment fleet. This data-driven approach empowers RELAM’s maintenance crews to anticipate issues, plan preventive maintenance, and avoid unexpected breakdowns. Predictive maintenance has further empowered RELAM to minimize downtime and reduce the need for excessive equipment replacement while promoting sustainable resource management.

iMarq is also a steadfast ally in supporting RELAM’s long-term sustainability goals. iMarq has helped RELAM to eliminate the need for paper documentation completely. This translates to saving thousands of paper sheets each year, reducing ink consumption, minimizing energy associated with printing, and eliminating the manpower required to create and manage paper documents. Additionally, there is a reduction in actual space needed to store paper documents and reports, whether for internal record-keeping needs or for mandatory requirements. These are all now stored electronically, are searchable and printable, on-demand.

Another sustainability advantage of iMarq lies in its ability to track part consumption patterns. With better insights into part usage, RELAM can now optimize its inventory management, ensuring they have the right items in stock without excess. This streamlined inventory control has reduced the frequency of deliveries, minimized transportation-related emissions and contributed to more efficient and sustainable supply chain practices.

RELAM sheds further light on this transformative journey at an exclusive roundtable hosted by Connixt. The roundtable provides a platform for industry professionals to delve into the intricacies of simplifying heavy equipment processes through digitization.

Join us on August 1st, 2023, at 11:00 AM PST to gain insights from industry experts, participate in interactive discussions, and explore the opportunities presented by RELAM’s digital transformation with iMarq.