Organizations have evolved from Reactive Maintenance – “When it happens, you fix it” (or the more common “if it ain’t broke, don’t fix it”) – to Periodic Preventive Maintenance. Periodic preventive maintenance is the most prevalent model because it relies on a set of policies and procedures and drives periodic inspections and servicing – thus determining further maintenance action.

Proactive and predictive maintenance represents the future direction of this progression, heavily depending on the collection and analysis of data, as well as the comparison between designed and actual performance metrics to initiate actions. This approach demands a high level of skill, operating within tight time frames while maintaining cost efficiency — a challenging balance given the scarcity of skilled professionals.

This is where the Internet of Things (IoT) steps in.

Industries are moving past their initial familiarity with IoT, venturing into a phase of active experimentation. From sectors like manufacturing and mining to construction and healthcare, organizations rely on a vast array of machinery, equipment, and tools. Effective management of these assets plays a crucial role in enhancing operational efficiency and impacting the financial performance of companies.

IoT-Enabled Predictive Maintenance

Enterprises are finding ways to automate the collection and tracking of data that is directly read from assets. This is basic IoT in action – systems can talk to the asset and the asset responds in the form of location, temperature, pressure, vibrations levels, miles, etc. Data gathered electronically – either in real-time or in batch mode – can be automatically evaluated for deviation from specs. This is the first step towards automating basic condition assessment.

IoT-Based Tracking

Organizations that have a lot of movable assets expend substantial time and effort to track and record the location of their assets. Geo-tracking sensors can be installed in an asset and a monitoring service can ping these sensors from the cloud in configurable intervals to know the exact asset location. It will also provide an audit trail of all previously known locations of the asset.

IoT-Based Monitoring

Monitoring can work with both fixed and movable assets. Using IoT sensors, asset condition can be monitored by collecting relevant data from sensors deployed on the asset. Relevant data can include temperature, pressure, vibration levels, etc. This monitored data can then be stored in the cloud, and algorithms can be built on top of this for proactive measures.

IoT-Based Asset Management

- Minimizing reliance on manual labor and boosting device efficiency: IoT enables the automation of the entire process, offering real-time updates on asset conditions, health, and other vital metrics to a central system.

- Enhancing repair and maintenance strategies to extend asset lifespans: Predictive maintenance sensors monitor data and performance, helping to avert unexpected equipment failures.

- Streamlining asset tracking with automated location data, geofencing, and GPS: This allows for the real-time monitoring of asset movement, helping to uncover and address inefficiencies or obstacles.

- Automating the reporting and monitoring of asset movement: This ensures continuous and automatic oversight of the components used in asset production.

- Automated updates for warehouse inventory management: Keeps inventory levels monitored and replenished proactively to prevent stock shortages.

IoT Use Case for Transportation

IoT is helping with asset maintenance by reporting on vehicle health. Temperature, pressure, and other data are collected onboard a light rail vehicle. This data is collected through a cell phone network by an IoT cloud framework. Preliminary analysis of data shows that some of the parameters are outside specified tolerance parameters which are relayed ahead of time to the workshop, which can then make the necessary preparation ahead of time.

The system can also be configured to automatically create a corrective/maintenance work order which can be issued to the appropriate department with a corresponding update to the back-end maintenance system. Everything from an oil change to a flat tire and everything in-between can now be part of automated reporting that allows your corporate teams to see vehicle needs from a desk and report those needs to field teams in real-time.

IoT Use Case for Utilities

For utilities, IoT is already making an impact when it comes to more efficient metering processes. Smart meters allow utilities the benefit of being able to read measurements remotely. This is saving utilities time and manpower as they can become more targeted in how they schedule in-person visits and inspections.

We have also seen great benefits when it comes to compliance and sustainability. Smart devices are not just reporting data, they are providing a faster and more efficient means to remotely operate and control output. This means that utilities can become smarter with energy efficiency – shutting off or slowing service during predicted downtimes and saving money by reducing waste.

IoT Use Case for Construction

The benefits of IoT in construction have few limits right now. The technology is still in its infancy for industry so new use cases are being developed every week.

But one of the strongest uses we’ve seen so far is monitoring material and equipment usage levels across all your jobsites. One of the biggest headaches for construction companies is inventory management. When you place an incorrect order quantity the delay can cost thousands or even hundreds of thousands, depending on the scope of the job, as you wait for new orders to be placed and delivered. Sometimes an incorrect order can bring an entire job to a complete halt.

The value of IoT for inventory management is invaluable because you’ve decreased the likelihood of human-based errors. When you’re able to connect everything, it allows for more accurate and exact data to be provided to your field teams when assessing future needs.

Connixt and IoT

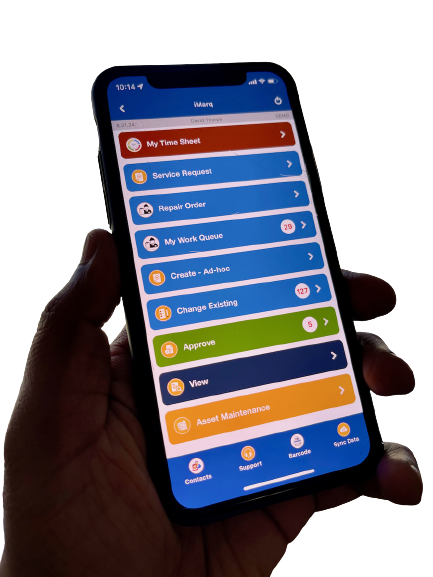

Numerous IoT applications across various industries are proving to yield immediate returns on investment (ROI) and enhance compliance. Connixt is broadening its offerings to incorporate an IoT framework into its Connixt Mobile Extension Framework (MXF™), marking a significant expansion of its cloud-mobile services. The company’s initial foray into IoT focuses on Asset Tracking, Monitoring, and Maintenance. In collaboration with partners and customers, Connixt is deploying non-invasive, swiftly implemented IoT solutions utilizing its comprehensive cloud-mobile suite, which includes both MXF and the iMarq™ Mobile app. These IoT applications from Connixt integrate effortlessly with its standardized solutions for work, time, asset, and compliance management, enabling tangible, actionable outcomes.

Aligning with our commitment to offering solutions that are SMARTER, SIMPLER, FASTER, we deliver intelligent results, straightforward adoption, and rapid deployment.