The pandemic has created new challenges for all areas of business, especially for managers responsible for industrial operations and logistics. Supply chain is now a common topic at both the water-cooler and family dinner tables. The lack of goods that were once plentiful and available, pre-pandemic, now is a key driving force for inflation worldwide.

If some good has come out of the pandemic, though, it is the fact that businesses are now forced to analyze their weaknesses in operational processes and supply chain management. As a result, many fundamental changes have occurred. This is great news for progressive managers who had already been pushing for changes that address operational deficiencies.

While there are no one-size-fits-all solutions to enhancing operational efficiencies, there are a few trends we can draw inspiration from to do better in 2022. Let’s take a look at what some of them are.

Remote Condition Monitoring

Remote working is no longer limited to specific sectors of the industry. Many organizations are now looking for remote technologies when it comes to asset maintenance and condition monitoring. In the pandemic era alone, approximately 60% of all American employees are working remotely, at least part of the time.

Remote condition monitoring services, with the right equipment, can help your crew with diagnosis, reporting, analysis, remote correction and/or scheduling on-site maintenance. This then saves time in transit and reduces the risk of exposure.

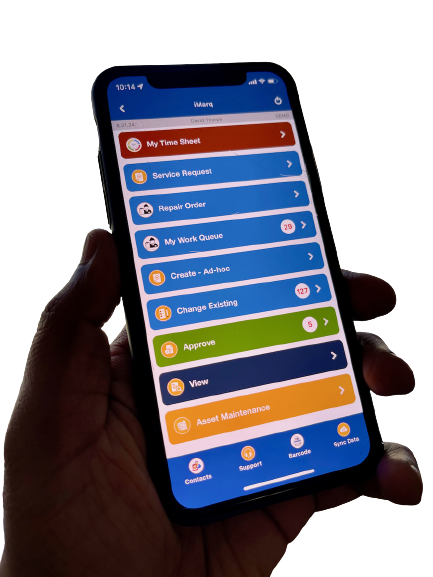

Products like Connixt iMarq can help with this. For example, iMarq can integrate with sensors on equipment or telematics devices on moving assets and trigger maintenance actions based on fault-codes and other signals.

EAM & Supply Chain Connectivity

There have been significant disruptions in the supply chain, which make on-time delivery difficult. To ensure a consistent, productive, and reliable supply chain, organizations can invest in technologies that further leverage their maintenance software (EAM/CMMS). For example, remote and instant inspections can be digitized, including Daily Vehicle Inspections, using mobile apps. These applications can then automatically update back-end systems, as well as trigger follow-on action when the vehicle pulls in for the next service. This innovative process can save valuable time for both drivers and fleet managers.

An industry’s size is not a limiting factor, as applications like Connixt iMarq are easy to deploy and integrate out of the box with backend maintenance software. This tool can also help with predictive maintenance to proactively address issues that might arise in the supply chain. Issues will then be flagged for attention, if not fixed quickly on the spot.

Technologies like iMarq also help in extracting greater ROI from your current EAM/CMMS investments. More on that here.

.jpg)

Trend Identification with AI/ML Tools

Artificial intelligence (AI) and machine learning (ML) can identify new and emerging trends to adapt to changing conditions. As such, more and more software is equipped with prescriptive analytics. As such, the use of artificial intelligence and machine learning can greatly improve identification of trends.

Digital SI & Critical Equipment Measurements

Industries need to transfer data in an efficient way. As such, Digital SI (international system of units) was created to help transmit calibration certification information electronically. This specific format ensures the sharing of paperless measurement traceability from all of the calibrations performed. This engulfs measurements in industry, legal metrology, trade, and science.

R&D & Product Development

3D printing is not a new concept and has been around for a while. However, organizations are now turning towards 3D printing to help them be as agile as possible in their product development. This is something one can expect to see more of in 2022. While it may not be the answer for big industrial parts, 3D printing can surely cover replacements for small and disposable parts. As it is cost-effective and tangible, it is a great trend for improving crew efficiency going forward.

With new challenges come new opportunities. The time we have spent in the pandemic has not been easy on any industry, but they have given the chance to come out stronger on the other side, finding new ways to improve processes. Isn’t that something worth looking forward to?

Reach out to Connixt today to improve your business operations by incorporating industry-strength cloud-mobile applications from Connixt.