While the origins of most enterprise applications can be linked to materials planning software designed to assist manufacturing operations, the vast majority of investments and advancements in enterprise technology have predominantly focused on supporting white-collar employees in back-office settings.

Significant investments have been made to overhaul finance operations, HR functions, and sales channels. There’s a clear push for digital transformation in office workflows, the frontline has rarely experienced similar advancements. These behind-the-scenes tech improvements play a crucial role in the broader journey. However, many in traditional industries overlook beginning with the aspect of their business that offers the highest ROI – their physical operations.

And perhaps for these reasons, physical operations are at a tipping point: the complexity of asset management and capital planning now exceeds what current tools can handle. Manual spreadsheets and traditional asset investment planning (AIP) software just doesn’t cut it for managing numerous assets in complex, evolving models. Add to this the rising costs, supply chain problems, labor shortages, and safety concerns.

For leaders, striking a balance between productivity, profitability, and worker safety is a major challenge, mainly due to the lack of a 360-degree view of their operations. The Motive Physical Economy Outlook 2024 report reveals that businesses in sectors such as trucking and logistics, along with oil and gas, have faced average losses exceeding $1 million, primarily due to economic instability, labor challenges, and operational inefficiencies.

The need for transformation is evident, with restricted visibility and isolated data impeding profitability and increasing safety hazards.

Navigating Economic Turbulence

Macroeconomic challenges loom large over industries such as trucking, logistics, and oil and gas. The last year has been particularly harsh for businesses in these sectors, with an average reported revenue loss of $867,634 as per the Motive report.

The report highlights how increasing expenses, including insurance premiums, fuel, maintenance, and accident-related costs, is the single largest threat for 59% of leaders. Economic instability, including fluctuating interest rates, inflation, and limited access to capital, ranks as a close second concern for 51% of those surveyed. Other significant concerns are labor shortages and retaining talent (45%), disruptions in the supply chain (42%), and operational inefficiencies (36%).

How do these figures affect those leading these sectors? Many are under immense mental strain, dealing with an overwhelming workload, with some clocking in nearly 60 hours a week. For some managers, the scarcity of workers makes it challenging to handle daily operations. Overall, it’s the unpredictability that most significantly dampens morale.

The next 12-month outlook presents a classic catch-22 situation. While half of the leaders in physical operations are optimistic about the economy improving in the next year, 32% predict a decline. Moreover, even as some supply chains appear to be recovering, 35% of leaders still expect continuous challenges in supply chain management.

The Rise of AI

Over the next year, the greatest opportunities are centered around technology. In the face of economic instability, a tight labor market, and increasing fraud risks, leaders view technology as one of the few consistent elements within their control. The top five prospects for physical operations in the coming 12 months are modernized technology and software (33%), economic stability (31%), enhancements in supply chains (31%), a rise in demand (30%), and improvements in operational efficiency (29%).

However, AI and its expanding influence will be the standout factor. Industry leaders are recognizing its potential and are set to make significant investments to center it in field management. In the construction sector, 40% of leaders see AI as a tool to improve worker safety, while this view is held by 31% in oil and gas and 30% in trucking and logistics. A notable 49% of C-suite executives expect AI to bring enhanced safety benefits, compared to 26% of managers and directors.

Construction and trucking see the top benefit of AI to be tracking assets and vehicles and optimizing utilization. Not all vehicles can be replaced, and not all labor gaps can be filled, but fleets can get more out of existing fleet operations by investing in smart solutions. According to the American Trucking Association, Trucks move roughly 72.6% of the nation’s freight by weight. The integration of AI can change the way goods and people move, making processes more efficient, sustainable, and reliable.

The overall reaction to AI is quite favorable. A major challenge for industry leaders is the lack of insights from their previous systems. Without real-time information, immediate responses become difficult. AI will change this aspect. The data that organizations possess can enable them to predict more accurately, respond more swiftly, and streamline processes, all thanks to the capabilities of AI.

Resolving Tech Issues

Technology has long been a challenge for traditional industries, and its absence is increasingly impacting physical operations. Leaders aiming to steer a safe, efficient, and profitable business need comprehensive visibility into all aspects of their operations. However, scattered data and disjointed tools are obstructing their ability to effectively manage on-the-road, on-site, and back-office activities.

Almost half (46%) of leaders use over ten different tools for operational management, with 30% finding it too numerous to count. Consequently, 58% end up spending most of their time addressing reactive issues rather than proactively overseeing their workforce, fleet, expenses, or assets and equipment. Many fleets are stuck using outdated tools and multiple systems, which complicates data handling. In fact, 20% of physical operations leaders still rely on pen and paper for managing workers, drivers, vehicles, equipment, and fleet-related expenses.

Leaders’ main issues with current physical operations technology are not having a complete view of operations (42%) and concerns over privacy and data security (42%).

The Drive for Advancement

AI can transform physical operations, especially if industries centralize their asset management. Centralized Asset Management is key, acting as a crucial connector for advanced maintenance methods.

- It offers a unified platform for all asset-related data, including real-time monitoring and predictive analytics.

- This centralization enables crews to shift from reactive to predictive maintenance, boosting efficiency and achieving top-tier asset care and operational excellence.

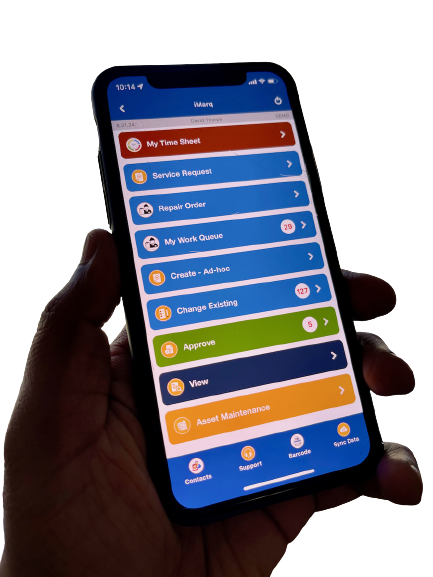

Solutions like iMarq are tailored to provide enterprises with greater business value while allowing field crews to digitize and automate maintenance and work management. iMarq, for example, effortlessly integrates data from any connected field asset, making it readily accessible to business users. Its no-code environment ensures quick implementation without altering existing backend systems and with minimal IT disruption. iMarq’s additional advantage lies in its collaboration with various technologies and platforms, including Motive, which empowers customers to harness the potential of integrated solutions for their physical operations. This seamless integration has empowered companies, including Mid South Transport, to achieve substantial benefits through the automation of operations, digitization of paperwork, and overall efficiency enhancement.

The growing demand for asset tracking, monitoring, and maintenance across various industries is another key driver in the asset management market. The complexity of assets, the necessity for real-time monitoring, and the need to comply with regulations all fuel this demand.

Predictive maintenance solutions like iMarq enable real-time asset performance tracking, early problem detection, and preemptive maintenance scheduling. This not only reduces maintenance costs and downtime but also enhances asset utilization. Moreover, businesses can leverage AI capabilities within such applications. In iMarq, the iBot feature, an AI-powered tool, interacts directly with your data. iBot goes beyond answering basic questions; it can provide insights and solutions akin to those from experienced team members, thanks to its access to your organization’s maintenance data.

2024 and Beyond

As we enter 2024, companies in the physical economy are anticipated to significantly ramp up their investment in technology to enhance operations. They recognize that the absence of a comprehensive view of their operations will persist in hindering their performance and, ultimately, their profitability.

Technology will be the key factor setting organizations apart. While no implementation is immediate, identifying the technologies that align with business objectives and developing a feasible strategy for their adoption will be the crucial initial step in the process.