Analyzing the friction between legacy EAM systems and the modern frontline workforce. A roadmap from reactive “firefighting” to intelligent asset stewardship.

The industry stands at a precarious inflection point. While boardroom discourse focuses on Industry 5.0, the shop floor struggles with foundational inefficiencies.

Annual cost of unplanned downtime for the world’s 500 largest manufacturers.

The cost of a stopped line in high-velocity sectors like automotive manufacturing.

Facilities that dedicate less than 40% of maintenance time to planned tasks.

Data reveals a significant “Preventive Maintenance Execution Gap.” While 88% of firms claim to use preventive strategies, actual performance lags far behind World Class standards.

The “Silver Tsunami” is accelerating the loss of tribal knowledge, yet the workforce remains critically underserved by technology.

Less than 50% of frontline manufacturing workers have access to mobile technology, despite 72% being eager to use apps.

As Baby Boomers retire, unwritten nuances of repairs leave with them. Paper-based systems fail to capture this critical institutional memory.

Challenge: State of Good Repair (SGR) backlog and paper-based “pre-trip” inspections (DVIR).

Digitization yielded 20% gains in labor efficiency, saving ~400 person-hours daily.

Challenge: “Last mile” connectivity. Technicians work in remote areas where cloud-only apps fail.

Offline Capability. Apps must sync seamlessly when connectivity is restored.

Challenge: Moving to Industry 5.0. High cost of downtime demands autonomous maintenance.

Digital Twins require accurate, real-time data from the floor to be effective.

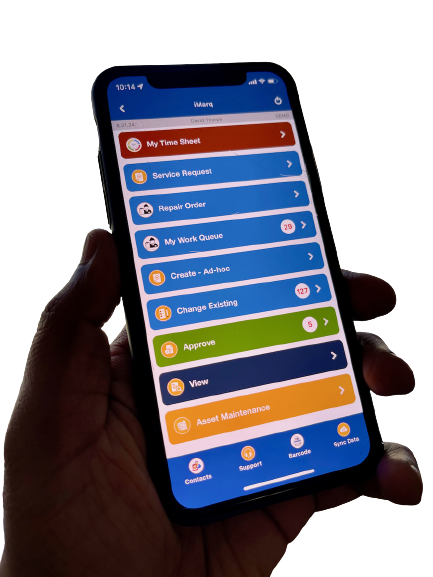

Legacy EAMs like IBM Maximo and SAP are robust “Systems of Record” but often lack field agility. “Mobile Overlays” bridge this gap without a rip-and-replace.

| Feature | Native EAM Mobile Apps | Specialized Mobile Overlays |

|---|---|---|

| Deployment Speed | Months to Years Requires complex server upgrades | Weeks Rapid deployment via Cloud/SaaS |

| User Experience (UX) | Clunky & Complex Mimics desktop screens | Consumer-Grade Intuitive, like using Uber or Amazon |

| Integration | Single Stack Only talks to one EAM (e.g., SAP) | Universal Connector Connects EAM + IoT + Telematics |

| Offline Capability | Limited / Unreliable Often requires constant connection | Full Offline Mode Auto-syncs when signal returns |

| Cost Model | High CapEx Expensive licensing fees | Low OpEx Scalable subscription model |

Stop treating data as the domain of engineers. Put real-time asset context in the hands of the frontline technician.

Dismantle silos. The future is automated, condition-based workflows triggered directly by asset telemetry.

If the app is hard to use, adoption fails. Choose solutions that mirror the simplicity of consumer apps.

Use voice-enabled AI (GenAI) to document expertise from retiring workers immediately.

See why 68% of organizations are increasing their predictive maintenance budget in 2025.

The State of Asset Maintenance 2025 report marks a pivotal shift in how the industry approaches reliability. As operational costs rise and workforce dynamics shift, the “run-to-failure” model is rapidly becoming obsolete. This year’s data reveals that successful organizations are no longer just maintaining assets—they are optimizing them through intelligence.

In this comprehensive report, we uncover the benchmarks defining 2025. The most significant trend? The aggressive adoption of AI-driven insights to streamline workflows and reduce downtime.

Key insights covered in this report include:

Download the full report to benchmark your current operations and future-proof your maintenance strategy.