In facilities maintenance, conversations often center around uptime, cost reduction, and compliance. While these are essential, there’s a broader financial lever that often goes underutilized: Asset Lifecycle Management (ALM).

ALM isn’t just a set of maintenance procedures—it’s a strategic discipline that directly influences long-term capital planning, operational performance, and return on investment (ROI). When supported by the right technology, it allows facilities teams to shift from reactive maintenance to lifecycle-focused asset stewardship.

The High Cost of Ignoring Lifecycle Thinking

Facilities often operate with a maintenance model that’s short-term in nature: repair after failure, replace when broken, and patch when needed. The result? Premature asset degradation, unplanned downtime, and frequent capital outlays. Without a lifecycle approach, organizations are locked in a cycle of deferred maintenance and reactive decisions, where the total cost of ownership quietly escalates over time.

According to the U.S. Department of Energy, neglecting preventive and predictive maintenance can increase overall asset lifecycle costs by 30% to 40%, while reducing energy efficiency and increasing failure rates [^1].

Consider an HVAC unit with a 15-year lifespan. Without regular maintenance guided by lifecycle planning, its operational efficiency begins to decline around year 7 or 8. Energy costs rise, repairs become frequent, and eventually, a full replacement is required years earlier than anticipated. Multiply this across dozens or hundreds of assets, and the financial impact is significant.

Defining ALM

At its core, Asset Lifecycle Management involves managing an asset from acquisition to disposal with an emphasis on maximizing its value throughout its useful life. It spans several stages:

- Planning and procurement

- Installation and commissioning

- Operation and maintenance

- Refurbishment or replacement

- Decommissioning and disposal

Each phase offers opportunities to improve performance and reduce costs—but only if data is collected, tracked, and acted upon continuously.

ROI is Not Just a Finance Metric—It’s a Maintenance Outcome

Organizations that adopt lifecycle-centric asset management consistently see stronger ROI from their maintenance operations. Here’s how:

- Optimized Capital Planning: Lifecycle data helps facilities teams make informed decisions about when to repair, refurbish, or replace assets. This leads to better timing of capital expenditures, avoiding unnecessary early replacements or costly emergency repairs.

- Improved Reliability and Performance: Assets that are maintained based on usage trends and lifecycle patterns perform better over time. This reliability reduces interruptions to operations and preserves productivity.

- Reduced Total Cost of Ownership (TCO): Through better tracking of maintenance costs, energy efficiency, and service history, teams can pinpoint underperforming assets and optimize their management, driving down long-term costs.

- Data-Driven Justification: With a lifecycle approach, facilities leaders can present data-backed proposals for investments or replacements, increasing credibility with finance and executive teams.

A GAO report on federal asset management noted that lack of lifecycle cost planning led to billions in deferred maintenance and inefficient use of public funds, underscoring the financial implications of poor lifecycle oversight [^2].

The Role of Maintenance Technology in Lifecycle Visibility

A major obstacle to effective lifecycle management is fragmented or incomplete data. That’s where modern maintenance technology plays a pivotal role.

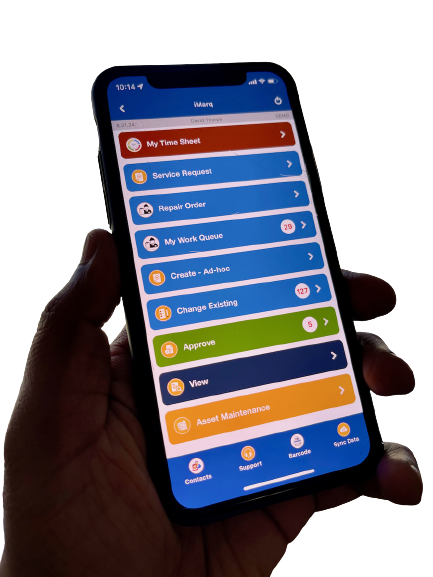

Today’s cloud-based CMMS (Computerized Maintenance Management Systems) and EAM (Enterprise Asset Management) platforms provide centralized visibility into asset health, maintenance history, and cost trends. More advanced systems integrate with IoT sensors to capture real-time performance data—enabling predictive insights and condition-based maintenance strategies.

For example, instead of relying on a fixed schedule for servicing critical equipment, facilities teams can now monitor actual usage, temperature, vibration, and other parameters to determine the most cost-effective intervention points. This reduces unnecessary maintenance while preventing costly breakdowns.

As the U.S. Department of Energy’s O&M Best Practices Guide outlines, predictive maintenance supported by real-time data can offer savings of up to 12% over preventive maintenance alone, and as much as 40% over reactive approaches [^1].

Bridging Facilities and Finance

One of the more transformative benefits of lifecycle-focused maintenance is its ability to connect facilities operations with financial outcomes. When maintenance teams can demonstrate how their decisions are extending asset life, lowering lifecycle costs, and deferring capital expenditures, the perception of maintenance shifts—from a cost center to a value driver.

Moreover, lifecycle data empowers finance teams to forecast depreciation more accurately, plan capital budgets with greater precision, and allocate resources where they generate the most long-term value.

Final Thoughts

ALM is not a trend—it’s a discipline that aligns operational rigor with strategic foresight. Facilities that treat assets as long-term investments, supported by data and modern technology, are better positioned to improve reliability, reduce cost, and ultimately, maximize ROI.

The maintenance function has evolved from simply “keeping the lights on” to becoming a critical enabler of asset value. For organizations seeking to build more resilient, cost-effective, and sustainable operations, lifecycle-centric asset management is not optional—it’s essential.

⸻

References

[^1]: U.S. Department of Energy – Operations & Maintenance Best Practices: A Guide to Achieving Operational Efficiency

https://www.energy.gov/sites/default/files/2013/10/f3/omguide_complete.pdf

[^2]: U.S. Government Accountability Office – Federal Real Property: Progress Made but Underlying Problems Continue to Hamper Reform – https://www.gao.gov/products/gao-17-745